CFD Analysis or computational fluid dynamics analysis, is a powerful tool used in the ventilation industry to optimize the design and performance of ventilation systems. In this article, we will discuss how CFD is used in the ventilation industry and the benefits it provides.

What is CFD Analysis?

This analysis is a simulation-based computational tool used to model and analyze the behavior of fluid flow, heat transfer, and other phenomena. In the ventilation industry, Computational Fluid Dynamics analysis is used to model and optimize the performance of ventilation systems, including air distribution systems, HVAC systems, and natural ventilation systems.

How is CFD Analysis Used in the Ventilation Industry?

Computational Fluid Dynamics analysis is used in the ventilation industry to optimize ventilation system designs and improve performance. By simulating and analyzing airflow patterns and temperature distribution in a space, Computational Fluid Dynamics analysis can identify potential issues and optimize the design of the ventilation system to improve airflow, temperature distribution, and air quality. This analysis is also used to optimize the placement of ventilation outlets and air inlets, ensuring optimal air distribution and minimizing energy consumption.

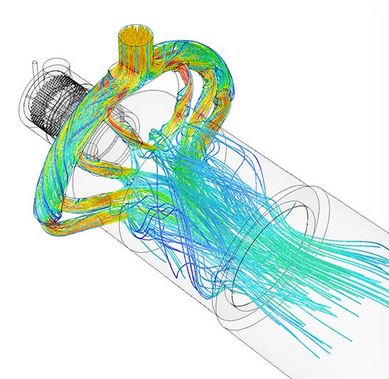

CFD Analysis

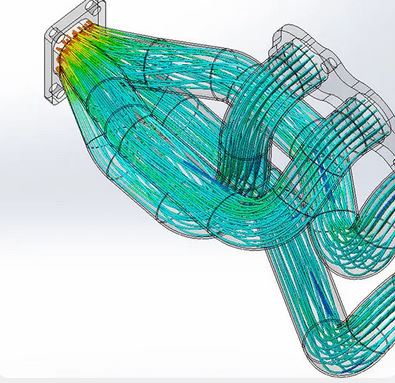

CFD Analysis

Benefits of CFD Analysis in the Ventilation Industry

1. Improved System Design: Computational Fluid Dynamics Analysis allows designers to visualize and optimize ventilation system designs before construction, resulting in a more efficient and effective system.

2. Enhanced System Performance: Computational Fluid Dynamics Analysis helps to identify potential issues and optimize the performance of ventilation systems, resulting in improved airflow, temperature distribution, and air quality.

3. Increased Energy Efficiency: Computational Fluid Dynamics Analysis can optimize ventilation system designs to minimize energy consumption, resulting in reduced energy costs and environmental impact.

4. Reduced Costs: By identifying potential issues early in the design process, Computational Fluid Dynamics Analysis analysis can help reduce the costs associated with system redesigns and construction.

CFD analysis is a powerful tool used in the ventilation industry to optimize the design and performance of ventilation systems. By simulating and analyzing airflow patterns and temperature distribution, it can identify potential issues and optimize the design of ventilation systems to improve airflow, temperature distribution, air quality, and energy efficiency. The benefits of CFD analysis make it an essential tool for designers and engineers in the ventilation industry, helping to create efficient and effective ventilation systems that provide a comfortable and healthy indoor environment.